Cleia builds new brick production line in Belarus

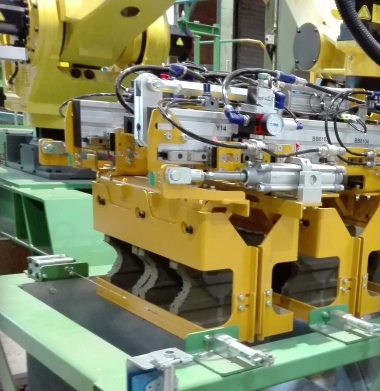

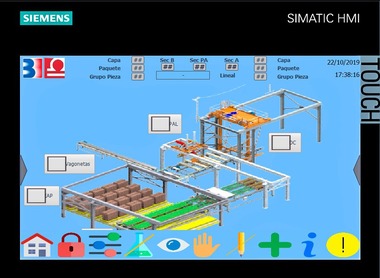

The production line developed by Cleia for masonry bricks is equipped with the latest generation of robotized setting machines for facing bricks and insulating blocks. This new production line starts from clay preparation and includes a new extruder group, a facing brick cutting line with chamfering device, automatic control circuits, two automatic transfer cars and a new robotized setting machine for facing bricks and insulating blocks.

New two-phase multi-wire cutters with chamfering device

To enhance the quality of cutting and chamfering, Cleia has developed a new multi-wire cutter with two cutting phases, which combines reliability and accuracy.

The clay column is cut in two steps in the multi-wire cutter. In the first phase, the column is cut into three slugs of equal length, then each slug is cut to the final brick size with four chamfered edges. This technology enables a decrease in the stress on the bricks and improves the quality of the cutting and chamfering operations.

In addition, an automatic control circuit for automatic loading of the wet and dry bricks as well as two transfer cars for handling the dryer cars will be installed. At the dryer exit, a robotized setting machine ensures a very accurate setting pattern for the facing bricks and the insulating blocks.

Cleia’s very successful cooperation with customers in Russia and the CIE states in recent years and its ability to supply turnkey plants of the highest quality prompted MZSM to entrust Cleia with this major project. Commissioning of the new production line is scheduled for early 2015.