Freymatic now supplying Leancut LC600

The tradition-steeped Swiss company Freymatic AG is known the world over for its high-quality cutting machines. The company‘s competences extend well beyond that single range, however, and harbour major innovation potentials: Freymatic also stands for made-to-measure solutions in the fields of automation and handling. From the engineering stage to final assembly, the customer‘s success and pertinent needs are of prime concern. Freymatic is globally renowned and valued as a competent, flexible, solution-oriented partner, whose innovative solutions are developed in a collaborative, goals-oriented process. Precision, feasibility and rapid implementation are the Swiss team‘s guidelines. Their successful cooperations are based primarily on personal exchange and commitment to the common cause, all according to the motto: “At Freymatic, I will always know who stands behind the project”.

Freymatic Leancut LC 600 for Wolfshöher Tonwerke GmbH & Co. KG in Neunkirchen am Sand

Just this spring, Freymatic‘s long-standing customer Wolfshöher Tonwerke in Neunkirchen had its brandnew Leancut LC600 successfully commissioned. As tradition-rooted both family-operated companies really are with their innovative products of consistent quality in their respective sectors, as traditional and collaborative is their mutual cooperation, too.

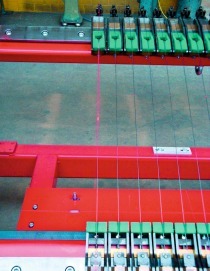

Freymatic‘s engineers were faced with the task of replacing an existing, analogue powered AM 600-TT-type Freymatic cutter with a new cutter driven by digital electronics. At the same time, the cutting functions were to be expanded to include cutting between two wires with scrap produced (trimming) and an increase in cutting length for refractory products up to 1050 mm. The existing auxiliary devices originally designed for the machine being replaced were to be retained and the new cutter integrated into the existing production line, despite quite limited space availability.

Considering the complexity of the task, Freymatic‘s new Leancut LC600 model and its specially designed cutting table appeared as the logical choice. Thanks to its modern design concept featuring modular construction, it was possible to design and build it to the customer‘s exact requirements. In this case, the cutting table had to be extra long to accommodate 1050 mm-long products between the two wires. The specially designed table enabled retention of the existing auxiliary devices. The table is equipped with a servo motor-powered linear drive, while the cutting wires have a servo motor with crankshaft. Equipped with latest-generation digital electronics and a menu-based operator‘s panel, the new cutter is extremely user-friendly.

With the commissioning of this Leancut LC600, the Swiss company has once again demonstrated its ability to implement customer-oriented, made-to-measure solutions in a timely, trouble-free manner.

Hall B2, Stand 128