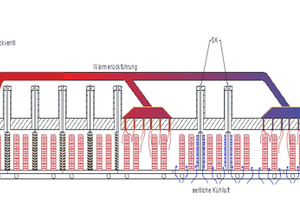

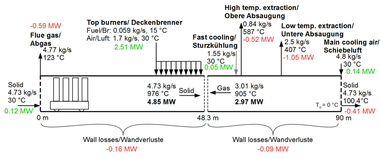

The electric tunnel kiln – challenge, heat transfer

It is the year 2050. Greenhouse emissions have been reduced by more than 80% in Germany. CO2 trading has long ceased in the building ceramics industry. The thermal processes, especially firing, are realized with electrical energy generated 100% on the basis of renewable energies. The energy consumption per kilogram brick has been lowered by 30% thanks to development work. A roofing tile, a backing brick or a clay paver kiln with average tonnage has an average power consumption of 0.4 KWh/kg brick product and is heated electrically. For this, special kiln engineering and process concepts are needed. This talk ventures a look ahead into a possible future.

Dr. Jens Petzold, KI Keramik-Institut GmbH, Meissen