11.12.2009 News: VDMA - Also with ceramics machinery cost and energy efficiency are playing an ever-increasingly important role

Ever since prices on energy develop in one direction only – this is with the exception of, for instance, the current economic crises: up and further up, energy and, with it, cost efficiency continue to play an increasingly important role in almost every field of machinery construction.

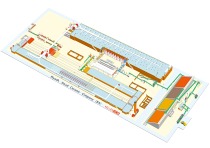

Mr Heiner Gausmann is standing next to a model of the cooling section belonging to a tunnel kiln which is used to burn bricks. “With our new system,” he says while pointing to the model, “without increasing the cost of electric power, 5 to 10 per cent of the cost of thermal enery can be saved during the process of making bricks.” Mr Gausmann (51) is head of process engineering and construction at Keller HCW GmbH – a worldwide operating constructor of plants and machines. The company which is situated in Ibbenbüren-Laggenbeck mainly builds machinery, machines and complete plants to manufacture any kind of tiles, bricks and paving clinkers. Mr Gausmann explained that about 5 years ago the company started developping this new system which they have been selling successfully since about 1 ½ years ago now.

Cooling system working even more efficiently

Keller HCW GmbH, the machinery constructor from Northrhine-Westfalia, presented the new system in which air is fed and circulated during the cooling process in such a way that an overheating of the kiln is prevented as much as possible. With this new technology, blowing off of surplus heat and, with this, also energy is reduced to an absolute minimum. “We were able,” so Mr Gausmann said, “to not only improve the efficiency of the cooling system significantly but also to increase the quality of the final products.” Due to the circulation of the air, there is a temperature comparability which leads to the fact that only 2 to 3 per cent of the final products break during the cooling process. “And this,” according to Mr Gausmann “is money in our clients’ pockets.” Within the next 3 years the amount of scrap is to be decreased to less then 1 per cent even, he explained.

At the very same point during the process, that is the cooling section, another system can be applied that was developed by Riedhammer GmbH. Here, the burner, which is used to heat the kiln, is fed with exhaust air (of 400° C) stemming from the cooling section instead of with ambient air. Mr Hartmut Weber, head of marketing at this Nuremburg-based company, stressed that with the help of this technology - compared to conventional systems - between 8 and 14 per cent of the energy cost could be saved. With one kiln – which mormally runs for more than 10 years – the investment is amortised already within 2 to 5 years – depending, of course, on its utilisation. There also is the possibility of refitting the new system into older machinery. Says Mr Weber: “The audience' reaction to our developments were positive all the way through!"

Amortised within one year only

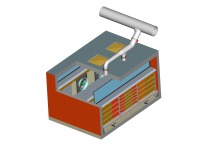

A new process presented by RTE Akustik + Prüftechnik GmbH, a company headquartered at Pfinztal near Karlsruhe, offers less energy efficiency but a very high cost efficiency. The technology used here sorts out defective work pieces with the help of a sound analysis. A small hammer hits the work pieces, such as bricks or cups, for instance. The sound produced that way is recorded by a microphone and then analysed. If the sound does not fulfill the parametres of an undamaged work piece, it is sorted out automatically. The final check, which is often still carried out manually, is no longer necessary. When operating 2 production lines and 3 shifts, the investment only takes one year to amortise, Mr Michael Kiefer, managing director of RTE, stressed.

A new granulating system used when producing ceramic tiles was developped by Maschinenfabrik Gustav Eirich GmbH & Co. KG. This new technology in which the amount of water used during the granulating process within the spray tower is reduced by 2 thirds to 12 per cent compared to conventional systems. With this new method, in order to get the 6 per cent of water which is needed so that the granulated material can still be processed, that is, can still be worked, only 6 per cent of water need to vaporise within the spray tower. In conventional technology, more than four times as much is required. The new method is therefore a very good one for saving energy cost. According to Mr Günter Hessling, who is responsible for process engineering at Eirich, it is about 50 per cent compared to the systems usually in place. In order to get the heat which is required during the vaporisation process, no gas but an induction heating is used. The induction heating works in such a way that the ready mix is heated up by vibrations and water then vaporises. This technology is comparable to what is happening in a micro-wave. This new system does not only help to improve your energy balance. It also makes the entire granulating process within the spray tower significantly shorter. And this, additionally, leads to saving cost. Says Mr Hessling: “A process which takes about three hours using traditional systems only takes about 15 minutes with ours – depending on the base materials used.”

Netsch-Condux Mahltechnik GmbH, a company headquartered in Hanau, further developped its opposed jet milll used in fine and ultra-fine grinding of dry products. Their system is patented. In this system, steam is used instead of compressed air to supply thepower. As steam, as Mr Frank Beltsohn, a graduate engineer, explained, is able to absorb more power than compressed air and can be pressed through the jets at a higher speed also, it becomes possible that the particles in the grinding chamber gain more speed than in traditional processes. Due to this, the material to ground also gets “a lot finer than in normal jet mills”. Says the sales manager: “We are talking of a size of under 1 mµ!”

70 per cent savings on energy cost

Dieffenbacher GmbH + Co. KG demonstrates that also with hydraulic press systems, energy cost can be reduced significantly with the help of intelligent solutions. The company from Eppingen has applied a basic prinicple when developping their new system - that is, that the efficiency factor of a hydraulic press gets higher when its length of stroke gets smaller. In their new system, a press is therefore driven mechanically until very shortly before the material, then the operating cylinder is locked mechanically, and finally, an oversquare pass is operated hydraulically to process the material. Says Mr Mathias Graf, engineering manager of the company: “Due to this new technology, we were able to reduce the energy cost by about 70 per cent compared to conventional devices.”

VDMA

Fachverband Bau- und Baustoffmaschinen

Lyoner Straße 18I 60528 Frankfurt/Main I Germany

T +49 (0) 69 66 03 12 57 I F +49 (0) 69 66 03 22 57

www.vdma.org